Packing Li-ion Batteries Must Know Some Basic Knowledges

Pack Methods:

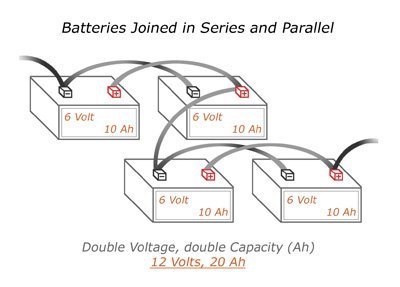

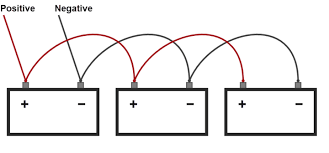

In series & in parallel

The battery is formed by single cells connected in series or in parallel, the capacity is increased in parallel, the voltage is unchanged, the voltage is doubled after the series, and the capacity is unchanged

For example: 3.6V/10Ah battery is consist of a single N18650/2Ah cell in 5 time parallel.

1. Parallel first and then series

Parallel connection due to the difference in internal resistance, uneven heat dissipation will affect the battery cycle life after parallel connection. However, when a single battery fails, it is automatically launched. Except for the reduction in capacity, it does not affect the battery working after parallel connections. The parallel process is strict. When a unit battery is short-circuited in parallel, which the current of the parallel circuit is very large, regarding to this problem, we could avoided it by adding a fuse protection technology.

2. Series first and then parallel:

According to the capacity of the entire battery set, the series connections is the first. such as 1/3 of the entire group, and finally connected in parallel, which reduces the probability of failure of the large-capacity battery.

Battery requirements:

select the corresponding batteries according to your own design requirements. The parallel and series batteries group require the same batteries type, the same batteries model, same capacity, same internal resistance, and the difference in voltage value is not more than 2%

In generally, when the batteries are connected in series and parallel, the capacity will loss 2%-5%. The more the number of batteries, the greater the capacity loss. –Whether it is a flexible battery or a cylindrical battery, multiple string combinations are required. If the consistency is poor, it affecting the battery capacity, the battery with the lowest capacity in a group determines the capacity of the entire group of batteries.

Pack Process:

1.Through laser welding, ultrasonic welding or pulse welding, these three are commonly used welding methods.

Advantages: better reliability,

Disadvantages: not easy to replace.

2. Through the elastic metal sheet,

Advantages: welding is no need, the battery is easy to replace,

Disadvantages: it may cause poor contact